ESD Static Sheild Cleanroom Packaging

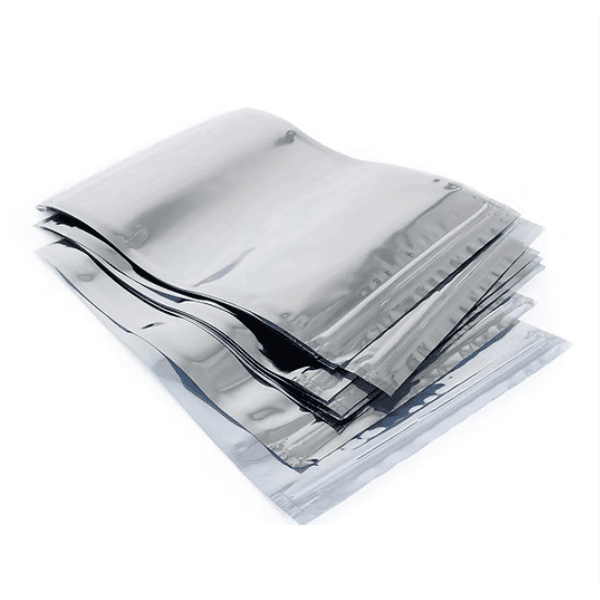

ESD static shield cleanroom packaging, including ESD film and bags, offers comprehensive protection against electrostatic discharge and contamination for sensitive electronic components. This specialized packaging features:

- Electrostatic Shielding: A buried metal layer provides superior electrostatic shielding, preventing static buildup and discharge, crucial for ESD static shield cleanroom packaging applications.

- Semi-Transparency: Allows easy visual inspection of contents without compromising the integrity of the ESD static shield cleanroom packaging.

- Heat-Sealable & Flexible: Ensures secure closure and adaptability for various product shapes and sizes.

- Polycarbonate Compatible: Suitable for a wide range of applications, particularly in electronics, our ESD static shield cleanroom packaging is compatible with polycarbonate materials.

- Contaminant-Free: Manufactured without Amines, Amides, or N-Octanoic Acid, ensuring a contaminant-free environment within the ESD static shield cleanroom packaging.

- Superior Material Composition: Constructed from Metal-in metalized PET/Poly with anti-static coating on both interior and exterior. Therefore, our ESD film and bags provide exceptional protection.

- Static Dissipative: Engineered to prevent static charge buildup, minimizing the risk of damage to sensitive components within the ESD static shield cleanroom packaging.

- Cleanroom Compatible: Manufactured in ISO-certified cleanrooms. Our ESD static shield cleanroom packaging meets stringent cleanliness standards.

- Durable Construction: High-quality materials provide excellent durability, tear resistance, and puncture protection for items stored within the ESD static shield cleanroom packaging.

- Customizable: ESD film and bag solutions are available in custom sizes and configurations to meet your specific needs.

Applications:

- Medical Device Packaging

- Pharmaceutical Packaging

- Semiconductor Packaging

- Aerospace Packaging

Specifications:

Material: Metal-in metalized PET/Poly with Anti-static coating on interior and exterior of film

Clarity: Metalic

Thickness: .00285

|

Properties

|

Value

|

Specification

|

|---|---|---|

|

Tensile Strength @ Break (LBS)

|

15

|

ASTM D 882

|

|

M.V.T.R. gm/100 sq in./24 hrs

|

0.35

|

ASTM F1249

|

|

Tear @ Break (LBS)

|

2

|

D-882

|

|

Puncture @ Break (LBS)

|

>10

|

ASTM 2065

|

|

Surface Resistivity @ 15% RH

|

<1012

|

ASTM D 257

|

|

EMI Shielding (DB)

|

<10 (1-10 ghz)

|

MIL B 81705 C

|

|

Electrostatic Decay (seconds)

|

<.05 (5000-0 volts)

|

EIA 541

|

|

Capacitance Probe (volts)

|

<10V, 20ms

|

EIA 541

|

|

Cleanliness

|

LVL 100

|

IEST-CC-1246E NASA JPG 5322.1

|